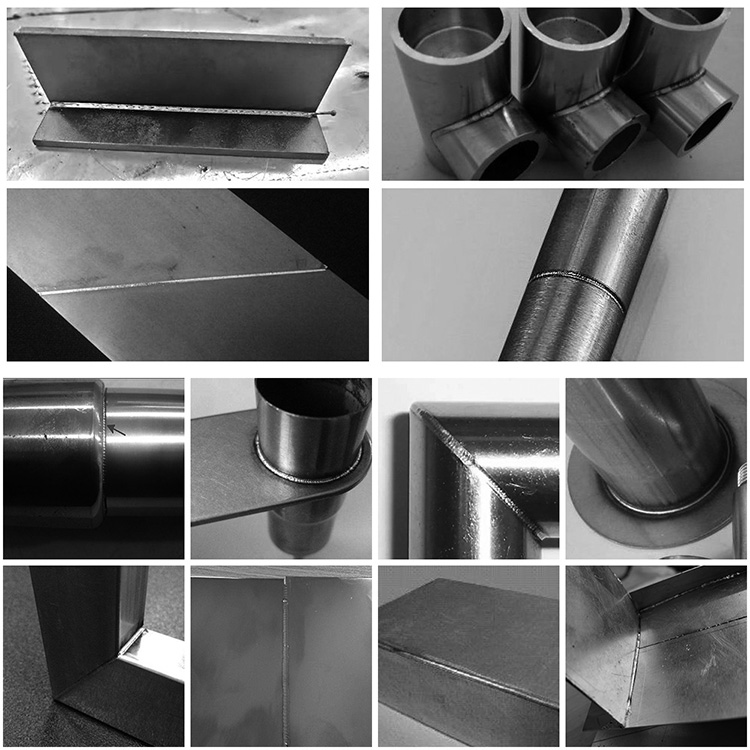

Laser vuam tshuab yog ib qho ntawm cov tshuab siv hauv kev vuam, thiab nws yog ib qho tseem ceeb ntawm daim ntawv thov

laser khoom ua technology.Vuam tshuab, thiab lwm yam., tom qab ntawd qhov kev lag luam twg tuaj yeem siv lub tshuab laser vuam?Ntawm no yog plaub

daim ntawv thov kev lag luam ntawm laser vuam tshuab.

Kev tsim khoom siv

Laser vuam tshuab tau dav siv hauv kev tsim tsheb hauv tsev thiab txawv teb chaws.Yav dhau los, CO2 laser vuam tshuab tau siv

nyob rau hauv Nyiv es tsis txhob flash taub qab vuam los txuas steel muaj dov coils.Hauv kev kawm txog ultra-thin phaj vuam, piv txwv li,

foils nrog lub thickness ntawm tsawg dua 100 microns tsis tuaj yeem welded, tab sis YAG laser vuam nrog tshwj xeeb tso zis waveforms Kev vam meej, laser vuam

nyob rau yav tom ntej dav

Hmoov metallurgy teb

Nrog rau kev txhim kho txuas ntxiv ntawm kev tshawb fawb thiab thev naus laus zis, ntau yam kev lag luam thev naus laus zis muaj cov kev cai tshwj xeeb rau cov khoom siv, thiab cov khoom siv

manufactured nrog tsoos technologies yuav tsis tau raws li qhov yuav tsum tau.Lub tshuab laser vuam tau nkag mus rau hauv kev ua haujlwm ntawm

hmoov metallurgy cov ntaub ntawv, uas tau coj txoj kev loj hlob tshiab rau kev siv cov hmoov metallurgy cov ntaub ntawv.Piv txwv li, pob zeb diamond

yog welded siv hmoov metallurgy cov ntaub ntawv koom nrog ntau txoj kev brazing.Vim muaj qhov sib txuas tsis tshua muaj zog thiab qhov dav tshav kub cuam tshuam,

tshwj xeeb tshaj yog tias nws tsis tuaj yeem hloov mus rau qhov kub thiab txias thiab siab zog yuav tsum tau, nws yuav ua rau cov solder yaj thiab poob.Siv lub laser

welding tshuab tuaj yeem txhim kho vuam lub zog thiab kub ua haujlwm.

Electronics kev lag luam

Laser vuam tshuab tau dav siv hauv kev lag luam hluav taws xob.Vim yog qhov chaw me me thaum tshav kub kub cuam tshuam, ceev cua sov concentration thiab qis

thermal stress ntawm laser welding, qhov zoo ntawm laser vuam yog qhia nyob rau hauv lub ntim ntawm integrated circuits thiab semiconductor ntaus ntawv

vaj tse, thiab laser vuam kuj tau siv rau hauv kev tsim cov khoom siv nqus tsev.Los yog lub thickness ntawm elastic nyias-walled corrugated

phaj nyob rau hauv lub thermostat yog 0.05-0.1mm, uas yog ib qho nyuaj los daws los ntawm ib txwm welding txoj kev.TIG vuam siv tau zoo thiab siv dav vim

mus rau qhov yooj yim nkag mus ntawm vuam, tsis zoo plasma stability thiab ntau yam cuam tshuam..

Auto kev lag luam

Tam sim no, lub laser vuam tshuab ntau lawm kab tau tshwm sim nyob rau hauv ib tug loj teev nyob rau hauv lub tsheb manufacturing kev lag luam thiab tau ua ib tug.

ntawm qhov ua tau zoo tshaj plaws ntawm kev lag luam tsheb tsim khoom.Muaj ntau tus kws tsim khoom siv laser vuam thiab txiav cov txheej txheem.Siab zog

steel laser-welded Cheebtsam yog nce siv nyob rau hauv kev tsim cov tsheb lub cev vim lawv cov khoom zoo heev.Vim lub ntim loj

thiab high degree ntawm automation nyob rau hauv kev lag luam automotive, laser vuam khoom yuav tsim nyob rau hauv cov kev taw qhia ntawm siab zog thiab multiplexing.

Post lub sij hawm: Sep-28-2022